Our manufacturing partners have kept pace with the rapid advances in the fish based Amino Acid (proteins) market where it is being used in as diverse a range as animal feed, aqua feed, nutraceuticals, pharmaceutical, and agriculture products with modern processes & uncompromising quality standards.

Our products are shipped to the UAE, Oman, Singapore, China, Taiwan, Japan, the USA, Thailand, Indonesia, Vietnam, South Korea, Canada, Peru, Chile, Colombia, Turkey, Egypt, Saudi Arabia, Sri Lanka, and Australia.

Fish Soluble Paste

Fish Amino Acid Liquid

Fish Amino Acid Powder (Hydrolysate)

Amino Acid Micronutrient Complexes

Granulated Organic Manure

Fish Bone Meal

Organic Pesticide

The best Selling Products

| Product Name | Use |

|---|---|

| Fish Meal | Poultry, Aqua & Animal Feed. |

| Crude Fish Oil | Animal Feed & Pharmaceutical Industry |

| Refined Fish Oil | Feed & Pharmaceutical Industry. |

| Sulphated Fish Oil | Paint & Leather Industry |

| Fish Soluble Paste | Wide variety of fruit and vegetable farming |

| Fish Amino Acid Liquid | For all types of Plants & Crops. |

| Fish Amino Acid Powder | For all types of Plants & Crops. |

| Granulated Organic Manure | For various horticulture & Agriculture Crops. |

| Fish Bone Meal | For soil amendment |

| Refined Fish Oil with Herbal Extract | For all types of Plants & Crops. |

| Amino Acid Micronutrient Complexes | For various horticulture & Agriculture Crops. |

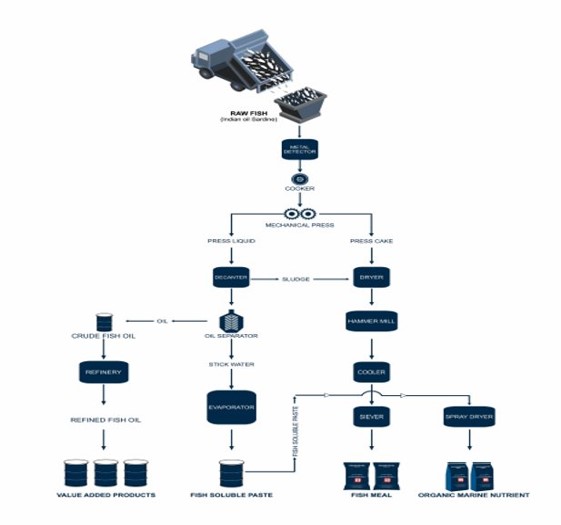

Manufacturing Process

The Indian Sardine Oil (Sardinella longiceps) is the main raw material used for the manufacture of fish meal and fish oil at our partners’ manufacturing plants. Abundant supply in excellent quality and high oil content makes this species ideal for the purpose.

The steam sterilized fish meal produced at our partners’ manufacturing plants are made by wet processes (i.e., raw fish are fed into double jacked steel cookers and cooked by steam). From the cooker the fish is fed into a twin screw press where water and oil are squeezed out.

The solids from the twin screw press, named fish cakes, are fed into steam driers. Dried fish meal is directed into a milling machine to finish powdering. They are then cooled in a cooler for bagging. The mixtures of water and oil are fed into a decanter to remove the suspended solids. This mixture is then put into a centrifuge to separate the oil from water. The oil obtained from these processes is crude fish oil. It is then refined or modified into various industrial products